Explain Different Types of Arc Welding

Slag inclusion weakens the joint by reducing its strength. From the welding point of view the arcs are of two types viz immobile or stationary or fixed arc and a mobile or moving or travelling arc.

Oxy-Fuel Welding Oxy-fuel welding is also known as oxy welding gas welding or oxy acetylene welding.

. Tiny globules of molten metal are transferred from the metal electrode to the weld joint. 12 Different Types of Welding Processes The Definitive Guide 1. Shielded Metal Arc Welding SMAW.

4 Different Types of Welding Procedures and When to Use Them 4 Main Types of Welding Processes. Automation with robotic arms is possible. The E6010 welding rods can give a good level of penetration but need a powerful welder that can provide a power density of up to 1 megawatt per.

Different types of welding and what they are used for MIG Welding. There are four main types of welding positions. D Heavy Coated Electrodes or Shielded.

Arc Electroslag Flux-Cored Gas Metal-Arc Gas Tungsten-Arc Metal Inert Gas Plasma Arc Shielded-Metal Arc Submerged Arc and Tungsten Inert Gas are the most widely. Types of Welding Arcs. The consumption of electrical energy is low as a maximum of 97 of heat energy can be utilized.

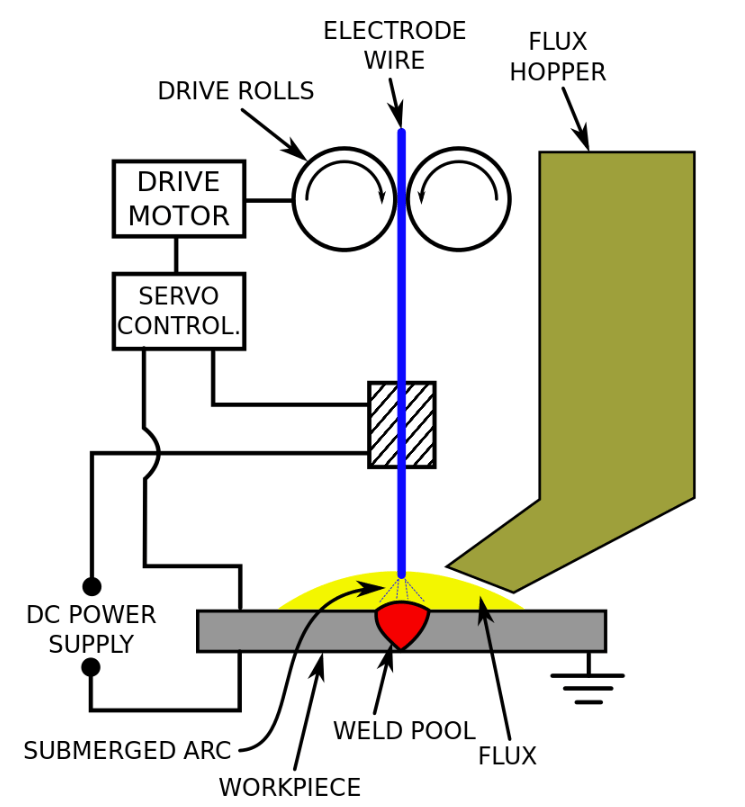

When flux a solid shielding material used in welding melts in the weld or on the surface of the weld zone this can happen. Non-Consumable electrodes remain intact through the welding process as the filler material is supplied separately. Submerged Arc Welding Machine 9.

The 9 Types of Welding 1. Consumable Electrode Methods Metal Inert Gas Welding MIG and Metal Active Gas Welding MAG Also known as Gas Metal Arc Welding GMAW uses a shielding gas to protect the base metals from contamination. Low welding equipment and process cost.

Arc welding has many subsections which can be broadly divided into two categories consumable electrode and non-consumable electrode welding. MIG welding is actually two. Flux-cored arc welding FCAW This type of arc welding uses tubular electrodes filled with flux.

These machines have their own advantages AC power supply is used where electricity supply is available. TIG Gas Tungsten Arc Welding GTAW Image Credit By. The arc welding process has the following advantages compared to other welding processes.

4 Different Types of Welding Procedures and When to Use Them 4 Main Types of Welding Processes Shielded Metal Arc Welding SMAW Flux Cored Arc Welding FCAW. Stick welding is a bit. Apply for a welding degree at NEIT.

It is a type of resistance welding process which can be used for joining together the ends of sheets wires rods or tubes. The current provided by the generator must not change when the welding machine moves the electrode in relation to the workpiece. Advantages of Arc Welding.

The arc may be used with or without filler. Stick welding is an example of consumable electrode welding whereby a stick of flux coated consumable electrode is laid onto the weld surface. B Light Coated Electrodes.

Consumable and non-consumable electrode methods. MIG Gas Metal Arc Welding GMAW. MIG welding is one of the easier types of welding for beginners to learn.

The electrode welding process is based on the direct current principle ie. A fixed arc is formed between a non-consumable electrode arid a workpiece. Wire consumption is low.

Welding speed is high. It works just as well with AC or DC models. According to its design the source must keep the current constant if the arc length changes due to the approach or distance in relation to the electrode.

Here electric arc is produced in the gap between the workpieces until the welding temperature is attained. The metals to be joined are placed flat and the welder passes the electric arc over them moving across the workpiece in a horizontal direction. Arc welding is the most common type of welding seen today.

C Medium Coated Electrodes. TIG welding processes use non-consumable electrodes. Stick welding also known as Arc welding is doing it the old fashioned way.

Polarity in Arc Welding Straight Reverse Alternating Polarity Arc welding is one type of fusion welding process where base metals are fused by applying heat in order to form coalescence. Flat position Also referred to as a downhand position the flat position weld is the easiest and often the first weld that new students learn. Slag is produced by stick welding flux-core arc welding and submerged arc welding and it is a toxic product.

This process can be categorised into two different types. Well the advancement of arc welding has brought to a reduction of supply voltage from 200-400 volts to 50-90 volts. Required heat is supplied by an electric arc constituted between positive and negative terminals of an electric circuit inbuilt with a power source.

What are the different types of Welding Electrodes. They have better corrosion resistance than high. Stick Shielded Metal Arc Welding SMAW.

MIG welding is a simple popular form of welding a novice can operate and master. These are century-old types of welding processes and improving. Welders can perform these two welds in all four positions.

Gas metal arc welding GMAW GMAW or MIG welding shields the arc with a gas like argon or helium or a gas mix. Types of welding rods. Both stick welding SMAW shield metal arc welding and MIG gas metal arc welding use consumable electrodes as they both add filler metal to the joint.

Prowelder87 Wikimedia The first type of welding is TIG welding which also goes by the names of Heliarc and gas tungsten arc welding GTAW. Slag inclusion is a type of weld defect. This is another of the most popular welding electrodes.

The process of welding that is used depends on a variety of factors but the form and thickness of the material is usually the deciding factor for which method is most effective. Any length can be welded without any interruption. Arc welding power source comes in two types direct current DC and alternative current AC.

The process gives high deposition rates. High-quality Welds are achieved with no fusion defects no porosity and slag inclusions. Different types of welding and what they are used for MIG Welding.

Following is an overview of various kinds of arc welding techniques. Then pressure is applied to produce a continuous weld. Arc welding is a type of welding in which an electric arc is created to heat and join metals.

With this type of welding the electrode is non-consumable and made of tungsten. This means it. Bare electrodes are made from either mild steel or low-alloy steel as a rule.

Types Of Welding Classification Of Welding Processes Welding Ndt

Different Types Of Welding Hotsell 54 Off Www Pegasusaerogroup Com

What Is Carbon Arc Welding And How It Works The Welding Master

Electric Arc Welding Definition Applications Types Working Studentlesson

What Is Arc Welding What Is Arc Welding Types Of Arc Welding

Principles Of Arc Welding Substech

Types Of Welding Process Online 50 Off Www Hcb Cat

Principles Of Arc Welding Substech

Different Types Of Welding Processes With Pictures

Are You Aware Of The Submerged Arc Welding Process Canam Bridges

Electric Arc Welding Basic Principle Construction Working Applications

Arc Welding Processes Ahss Guidelines

Types Of Welding Tri State Fabricators

4 Main Types Of Welding Processes With Diagrams

What Is Arc Welding Types And How Does It Work Engineering Choice

What Are Electric Arc Welding Types Extrudesign

Welding Types What Is Welding Classifiction And Welding Symbols

Comments

Post a Comment